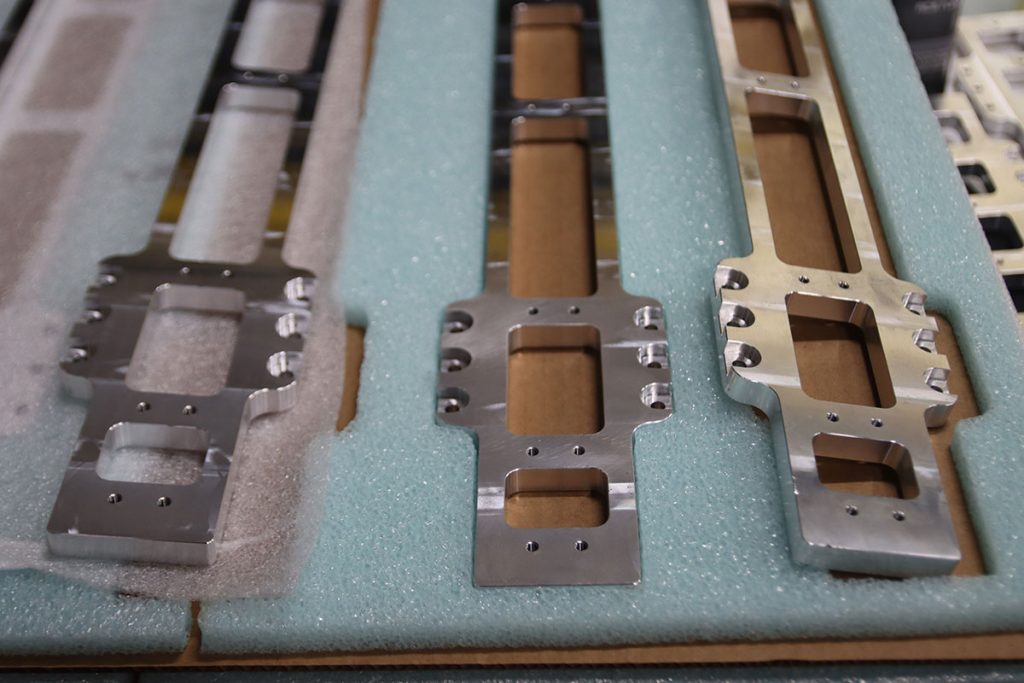

Laser Cutting Services

At SoFlo Machining, we specialize in precision machining and manufacturing solutions and offer laser cutting as part of our capabilities. Our state-of-the-art equipment can quickly make intricate designs and shapes on a wide variety of materials including:

- Glass

- Metals

- Plastic

- Wood

The technology we use creates environmentally friendly, high-quality designs.

Laser cutting is a cost-effective way to manufacture without having to worry about the cost of setup and tooling. No matter the size of the project, SoFlo Machining can create high-precision laser cutting services with a fast turnaround rate.

What Is Laser Cutting?

Laser cutting is a thermal separation method that uses a highly focused stream of light to cut through materials. The intensity and precision of the laser melts or vaporizes the material on contact. Once the laser makes contact with the surface, the cutting process begins.

The laser follows the selected pattern and separates the material. Because the equipment doesn’t produce residual stresses, it can be used on most types of materials. Laser cutting services are an ideal option for nearly every industry. It offers several benefits over traditional cutting options.

Laser Cutting Advantages

Almost any industry can benefit from laser cutting services. It is commonly used in aerospace, automotive, electronics, and tool machining. Some advantages of trusting SoFlo Machining with your projects include:

Non-Contact

Drill cutting, as opposed to laser cutting, requires the tools to come into direct contact with the materials. Over time, this can wear down the drill. Worn-down tools don’t cut as precisely and can damage or even ruin a project. Because laser cutting doesn’t require tools to make contact with the materials, SoFlo Machining can guarantee a clean job every time.

Accuracy

No matter the project, you deserve accurate results. Laser cutting allows the experts at SoFlo Machining to hyperfocus the beam to drill precise small holes. This is a huge advantage over traditional cutting. Having the ability to control the size of the cut produces consistent and repeatable results. SoFlo Machining uses Computer Numerical Control (CNC) methods, which produce zero defects with a quicker turnaround time.

Sustainability

Unlike more traditional drilling methods, laser cutting has the ability to cut and drill difficult materials. Conventional drilling often requires a number of specialty drills that can still produce subpar results. They run the risk of burrs and sharp edges because the bits can’t produce small enough holes. Due to the fact normal drills have to make contact with the materials, they are often too weak for sturdy materials like metals and too strong for delicate materials like glass. SoFlo Machining’s laser cutting services can expertly cut a variety of difficult materials.

Quick Turnaround

Because the laser does not have to be manipulated by hand, it works much faster than conventional drills. The optical system configuration and cutting head movement define the speed of the drill. Our fast turnaround rate allows you to continue business as usual. We understand that completing projects on time is critical to customer satisfaction. Because laser drills are less physical, SoFlo Machining can customize and produce your project in a timely manner.

Environmentally Friendly

SoFlo Machining has a long history of being mindful of the environment. Because laser cutting is more precise than traditional means, they require less energy to operate and produce less waste. As we use only the best equipment available, our machinery is built to last. The increased lifespan means less frequent replacements. Long-lasting machinery means fewer parts end up in the landfill. Another environmental benefit is that since laser cutting doesn’t require lubricants, less pollution is produced.

Cost-Effective

More and more people and businesses are turning to laser cutting to complete their projects. One of the main reasons is that it is more cost-effective than conventional drilling. One of the major reasons SoFlo Machining is able to keep costs down is that our machinery is more energy efficient than the alternative. Also, traditional drilling produces tons of scrap materials that are costly and difficult to dispose of. Laser cutting, on the other hand, keeps material waste to a minimum.

Markets Supported

Whether you need a short-term run or a long-term, high-volume production run, SoFlo Machining offers custom, cost-effective solutions to meet your needs. Nearly every industry can benefit from laser cutting services. Some of the most popular markets we support include:

- Aerospace: The aerospace industry must adhere to strict manufacturing regulations. SoFlo Machining has all the needed certifications to offer laser cutting solutions.

- Industrial: Heavy equipment and machinery are the backbone of our country. SoFlo Machining proudly manufactures custom laser cut parts.

- Marine: From pleasure craft to industrial turbines to transport ships, SoFlo Machining offers viable laser cutting and manufacturing solutions to this vital market.

- Medical: Innovation and quality are crucial to the medical industry. SoFlo Machining can create precision medical instruments through laser cutting.

- Multi-Markets: Industry demands are constantly changing. SoFlo Machining prides itself on providing flexible, creative, and diverse approaches to any market.

- Space: As the space industry continues to evolve, it’s critical to provide precision instruments. SoFlo Machining has the ability to create dynamic laser cut parts.

The SoFlo Machining Advantage

For nearly a decade, SoFlo Machining has taken pride in providing our clients with service you can trust. We follow the strict guidelines that come with AS9100D and ISO 9001 certification. These certifications standardize quality management systems to ensure the production of the highest quality laser cutting services possible.

Our dedication to innovative engineering provides economic solutions for all your laser cutting needs. From concept to completion, our team will work with you to ensure your project is completed to your specifications and on time.

Our precision part quality record proves our ability to laser cut parts reliably and meet all of your requirements. Every part we manufacture is treated with the utmost care upholding the same exact high-quality engineering standards.

No matter the order, you can trust our laser cutting services for all parts. If you have any questions about laser cutting or any of our other services, call us at (954)-255-3108 today!